So in cases such as the one pictured above, an increase to the splice length may be necessary to satisfy this requirement.įor reasons I can't quite fathom, though, the Brazilian code explicitly states that splices between different diameters must adopt the larger diameter, so that's what I'm stuck with. However, both codes do allow distances larger than this limit so long as the splice length is increased accordingly. In this case, there's the question of which $\phi$ to use, and I honestly don't know. The Brazilian code NBR-6118 and EC2 both put that limit at $4\phi$ or 50 mm. The codes usually define a maximum distance between lapping rebars.

/GettyImages-186366540-591fbd743df78cf5fad32661.jpg)

The arrows roughly represent the furthest distance that tension needs to travel from each bar. In the figure below, for instance, assume this is a splice section, with the tension from the large red bars being transferred to the small blue ones. However, if you are splicing multiple rebars in the same position, going from a few large diameter bars to many smaller ones, an incremement to the splice length may be required. So there's no reason to design your splice to withstand a force larger than the yield strength of the smaller bar.

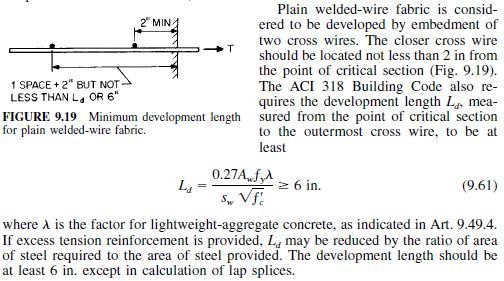

When determining the lap splice length, d is calculated without the 12-inch.

#Lap splice lengths plus

If the tensile force is larger (say, equal to the yield strength of the larger rebar), then the smaller rebar will rupture immediately after the splice. to be greater than 1.0 db plus twice the concrete cover. length in table shall be factored for the following conditions horizontal bars more than 12' above bottom of cast member: 1.3xtable length light weight concrete: 1. Therefore, if you are splicing two rebars of different diameters, the maximum tensile force that can be transferred via the splice is equal to the yield strength of the smaller rebar. length shown conform to non -seismic provisions of aci 318 for uncoated bars enclosed by properly spaced ties or stirrups 2. However, once the splice is over, all the tension from the first rebar has been transferred to the other one, which must also be capable of withstanding that same tension. Since concrete is very weak against tension, large lap lengths are required such that the stress at any point in the concrete is not excessive. What is a splice? It is when tension force in a rebar is transferred to the concrete via adhesion and then to another rebar. The use of the smaller diameter is theoretically correct.

0 kommentar(er)

0 kommentar(er)